roller chain size guide

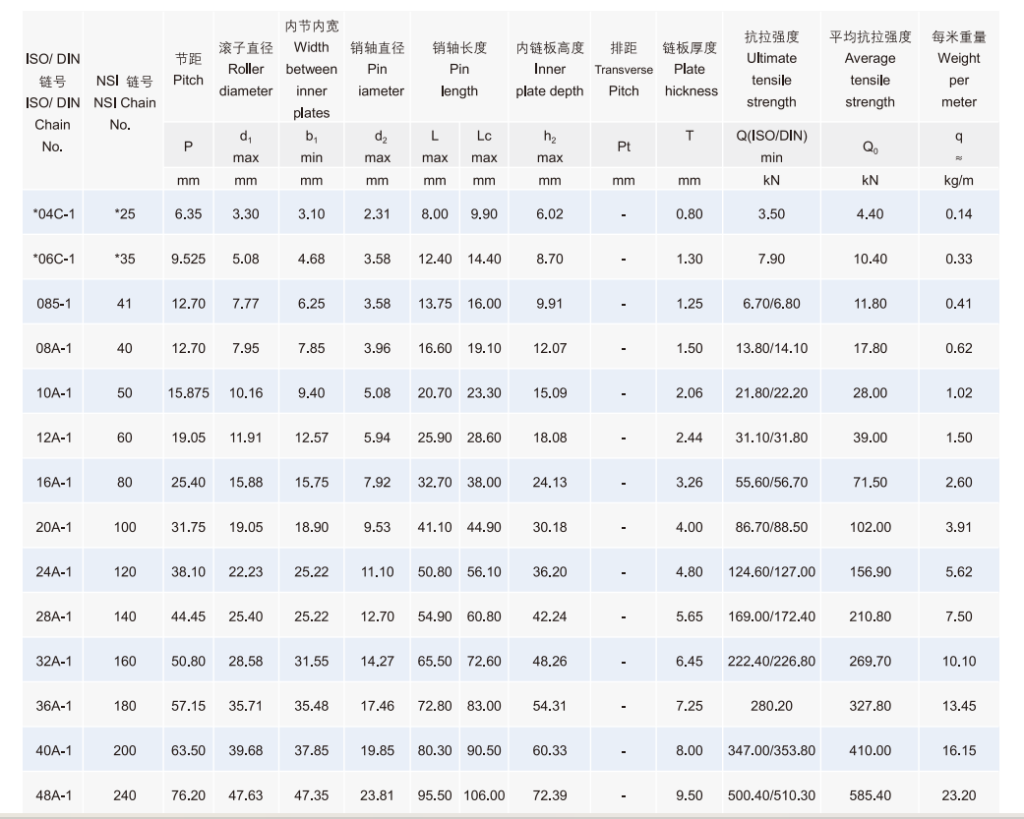

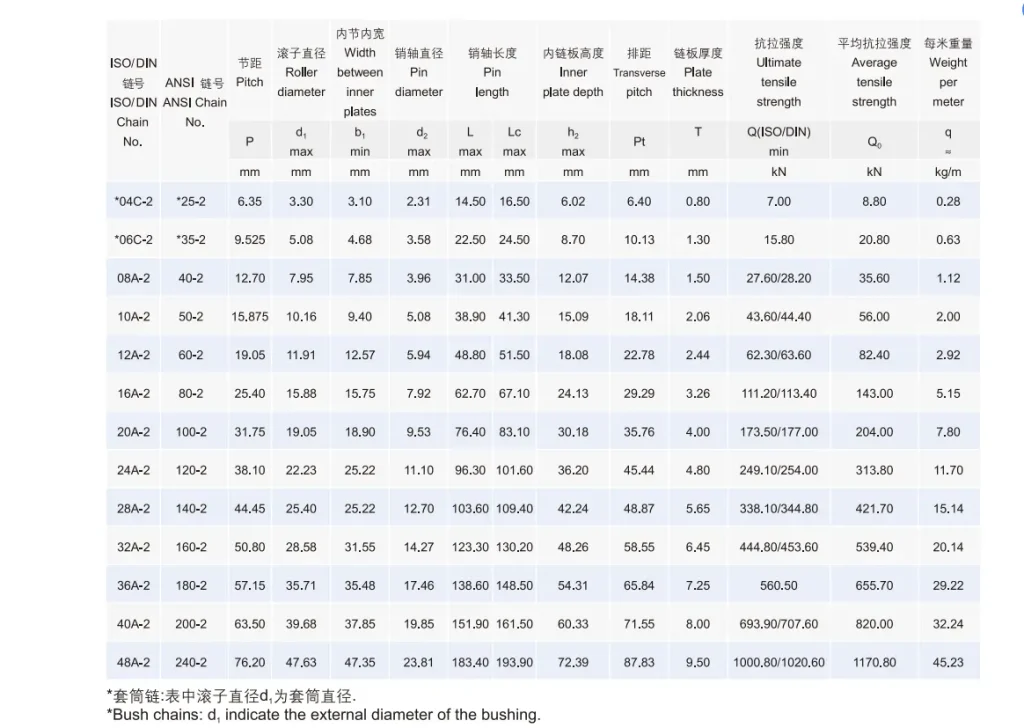

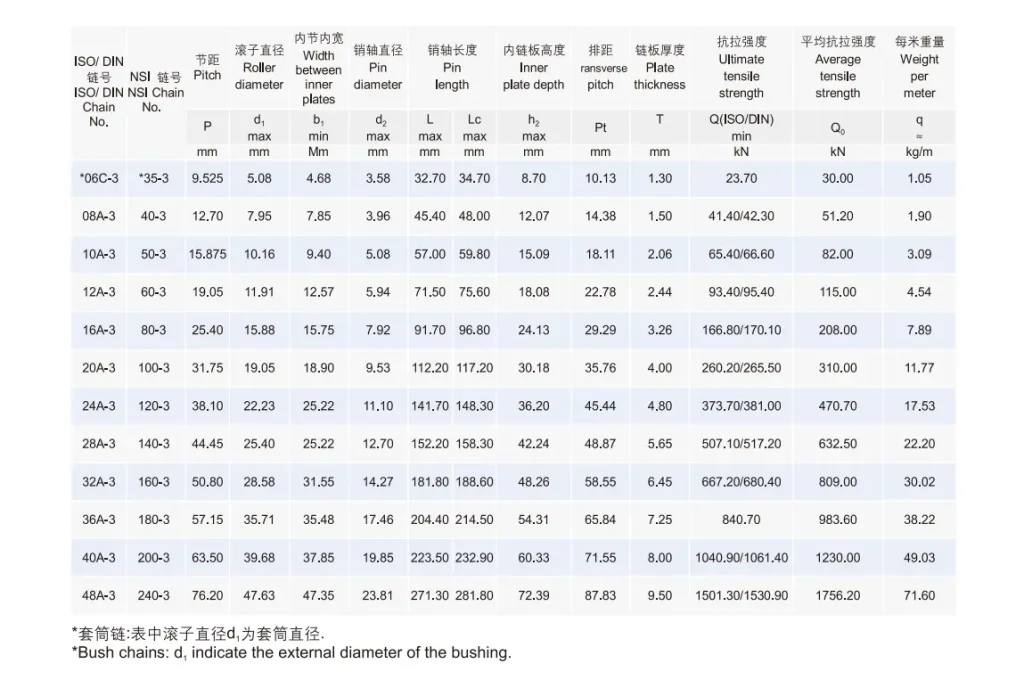

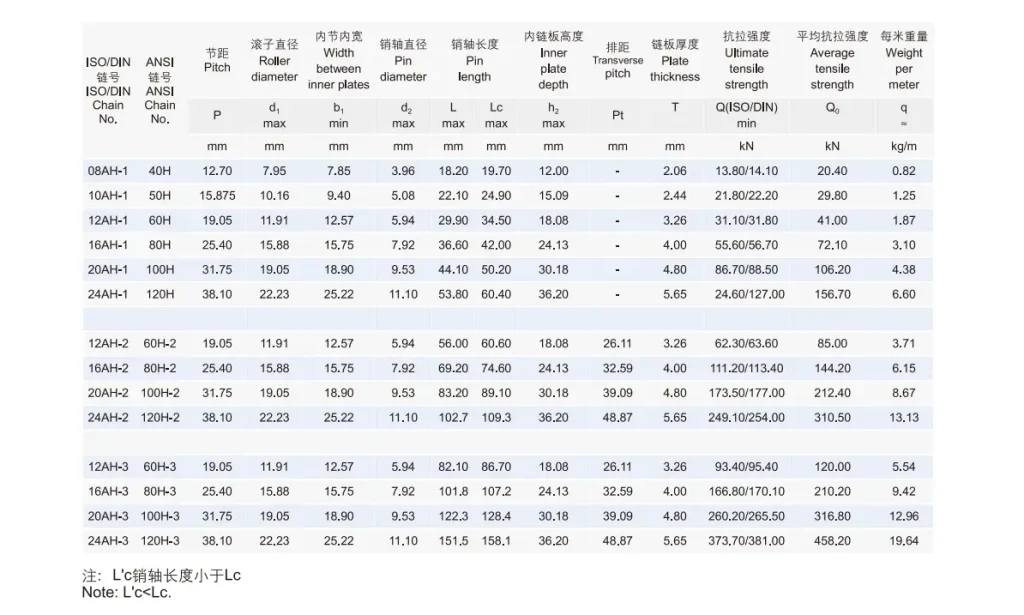

Knowing the right roller chain size is crucial for optimal performance, durability, and reliability. It reduces wear, boosts efficiency, and enhances the lifespan of industrial and agricultural machinery.

At Universal Chains, our precision-engineered roller chains are made to meet diverse applications, from industrial conveyors to heavy-duty agricultural equipment. With advanced heat treatment and top-quality materials, they deliver exceptional durability and performance.

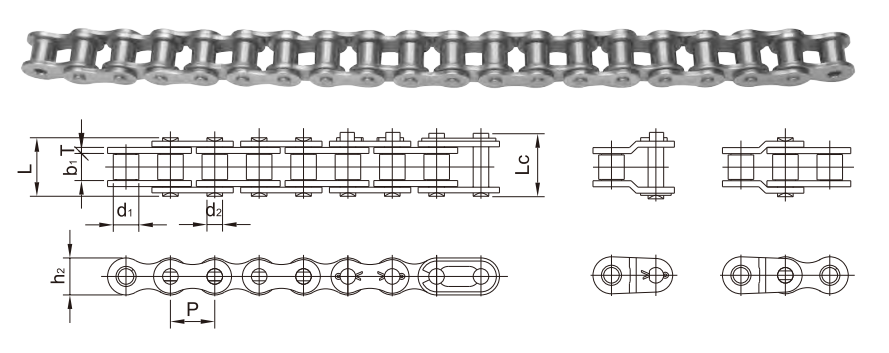

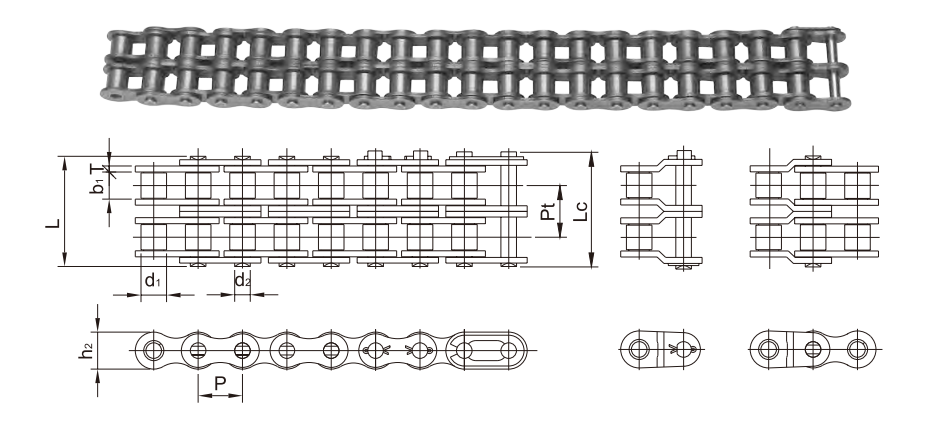

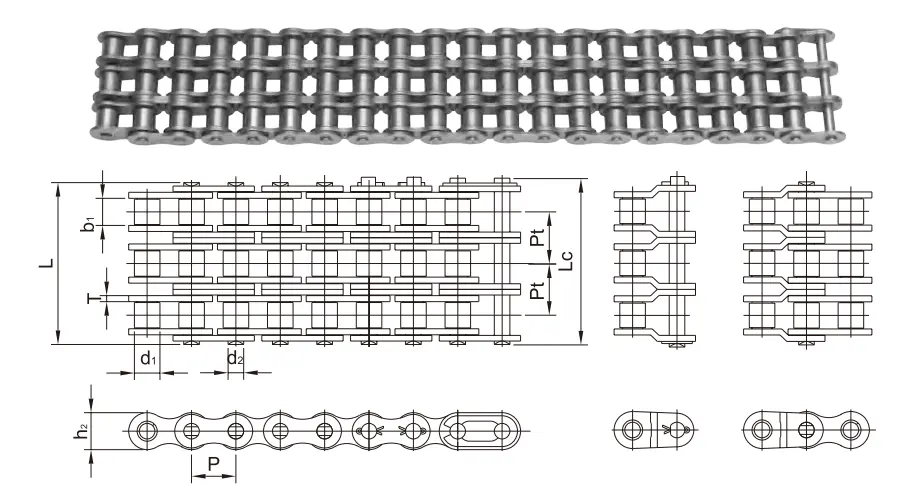

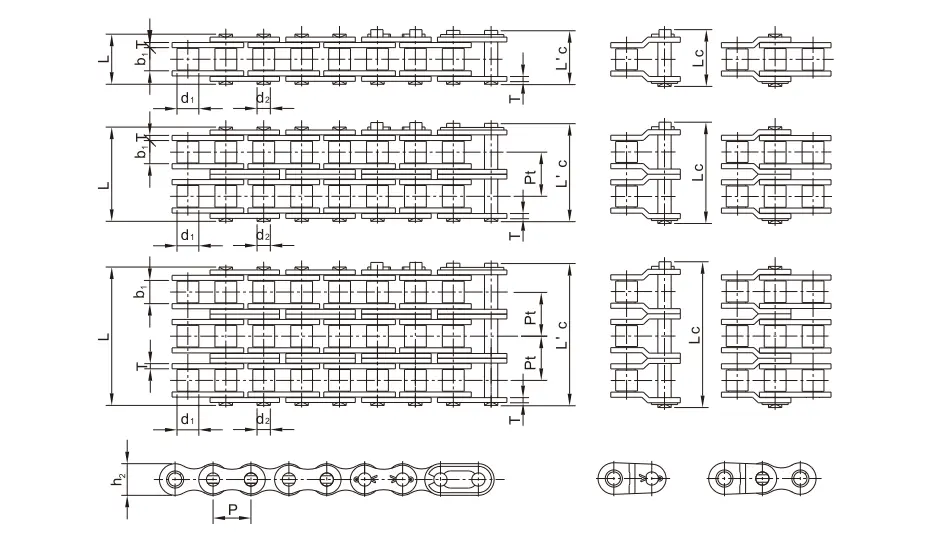

We offer single-strand chains for compact systems and triple-strand chains for high-demand operations. All our products comply with ANSI and ISO standards. With a variety of sizes and configurations, finding the right chain for your needs is simple.