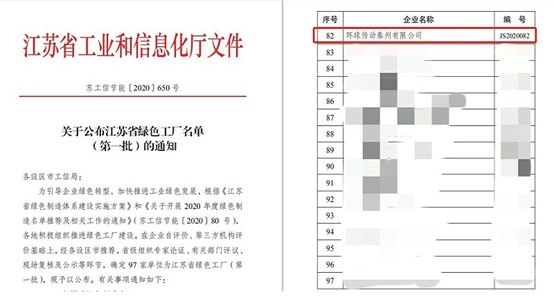

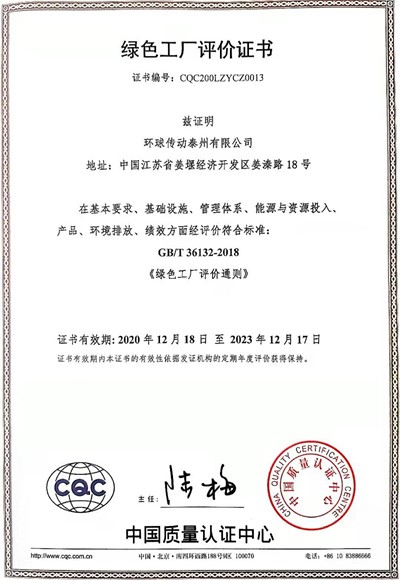

Am 22. Dezember 2020 kündigte das Ministerium für Industrie und Informationstechnologie der Provinz Jiangsu die erste Charge grüner Fertigungslisten an. Unter ihnen war Universal Transmission Taizhou Co., Ltd., eine Tochtergesellschaft von Suzhou Universal Technology Co., Ltd., auf der Liste und gewann den Titel der ersten Charge einer „grünen Fabrik“ auf Provinzebene.

Seit der Gründung des Unternehmens hat sich Universal Transmission Taizhou Co., Ltd. stets an die Politik der nachhaltigen Entwicklung gehalten, sich auf eine umweltfreundliche und qualitativ hochwertige Entwicklung konzentriert, das eigene Potenzial des Unternehmens voll ausgeschöpft und die Umsetzung einer umweltfreundlichen Fertigung geleitet und standardisiert Fabriken und Investitionen in Infrastruktur, Managementsysteme, Energieressourcen und Produkte. Umwelt und andere Aspekte wurden große Anstrengungen unternommen, um die allgemeine Verbesserung und Optimierung der F&E-, Produktions- und Herstellungskette der Kette zu realisieren.

Stärkung des Infrastrukturbaus und Verbesserung der neuen Entwicklungsdynamik des Unternehmens. Universal Transmission Taizhou Co., Ltd. konzentriert sich auf den Entwicklungstrend der traditionellen Industrieumwandlung und -aufrüstung und nimmt die intelligente Werkstatt als Ausgangspunkt, besteht auf mechanisiertem Ersatz und Automatisierung und fördert die Umwandlung von Produktionsanlagen in vollständige, große Maßstab und intelligente Produktionsanlagen. In den letzten Jahren wurden mehr als 10 Millionen Yuan in die Einführung automatischer Produktionslinien für die Wärmebehandlung investiert. Das Intelligenzniveau wurde erheblich verbessert, wodurch potenzielle Sicherheitsrisiken effektiv reduziert und ein hochwertiges Entwicklungsmodell mit „starker Ausrüstungskapazität, hoher Systemeffizienz und ausgezeichneter Arbeitsorganisation“ geschaffen wurde.

Das Unternehmen Universal verbessert umfassend das Managementsystem für grüne Fabriken. Das Management von Arbeitssicherheit, Umweltschutz, Ressourcenmanagement wird ernst genommen. Die Umweltverträglichkeitsprüfung wurde ernsthaft durchgeführt und die Umweltschutzanforderungen für den Wiederaufbau und die Erweiterung strikt befolgt. Neue Projekte folgen einem Standard von „drei simultanen“ Systemen, um simultanes Design, simultane Konstruktion und simultane Produktion zu erreichen. Im Projektbau liegen sowohl die Umsetzungsquote der Umweltverträglichkeitsprüfung als auch die Vollabnahmequote bei 100%, was dazu beiträgt, eine solide Grundlage für die Umsetzung des Green Factory Plans zu legen.

Seit 2020 führt das Unternehmen eine äußerst emissionsarme Umwandlung und ein Ressourcenrecycling durch, was den Bau grüner Fabriken auf ein höheres Niveau fördert. Eine spezielle Gruppe wurde eingesetzt, um den Zielbewertungsplan für Energieeinsparung und Umweltschutz zu überarbeiten und eine vollständige Bewertung zu erstellen, um ein energiesparendes Netzmanagementnetz für Büros und Werkstätten zu erreichen. Die Anlage spielt eine gute Rolle bei der Einhaltung der nationalen Standards für Schadstoffemissionen. Die Umweltbegrünungsrate hat mehr als 60% erreicht.

Die Auswahl als grüne Fabrik auf Provinzebene trägt dazu bei, die Markenbekanntheit von Universal zu steigern. Auch in der Öffentlichkeit findet das Unternehmenskonzept der grünen und qualitativ hochwertigen Entwicklung Anerkennung. Um einen Beitrag zur Förderung der grünen und nachhaltigen Entwicklung der Kettenantriebsindustrie zu leisten, wird Universal weiterhin Anstrengungen zur Energieeinsparung und zum Umweltschutz unternehmen. Wenn Sie an unseren Kettenprodukten oder detaillierteren Informationen interessiert sind, können Sie sich gerne an den Online-Kundendienst wenden, um sich beraten zu lassen. Wir freuen uns auf die Zusammenarbeit mit Ihnen!

Suzhou Universal Technology Co., Ltd. konzentriert sich seit 50 Jahren auf die Herstellung von Ketten. Kettenprodukte umfassen Antriebsketten, Förderketten, Plattenketten, technische Ketten, Rolltreppenketten, Spezialketten, Landmaschinenketten usw. Wir sind hier, um der Branche zu helfen, Effizienz und Entwicklung zu steigern.