Attachment roller chains integrate useful features along their inner and outer plates to enable connections, adjustments, and more. Let’s explore what defines these versatile chain types and where they add value.

- Features welded attachments for functional enhancements

- Allows adjustable chain length and simplified connections

- Reduces assembly labor and component costs

- Broadens applications across industries

In industrial environments, the typical plain roller chain doesn’t always meet needs out of the box. That’s where roller chain with attachments steps in – delivering specialized functionality to simplify mechanical designs.

Defining Attachment Chain

At its core, attachment chain begins life like any other ANSI or ISO power transmission roller chain before entering secondary processing. Here, useful features get welded directly onto the chain’s inner and outer plates at fixed intervals.

Attachments might include pins, tapped holes, threaded studs, rings, hooks and more. They transform the chain into a sort of flexible fastening system or integrated mechanism by enabling connections, adjustments, and customized configurations.

Benefits Over Standard Chain

This embedded functionality unlocks several advantages over plain roller chain:

- Adjustable lengths eliminate the need to order fixed sizes. Chains can be connected or disconnected via attachments as needed.

- Mechanisms with moving joints are simplified by using chain as a flexible coupling.

- Attachments enable quick connections to other hardware like motors or guides.

- Assemblies require fewer separate components like fasteners, pins and brackets.

The flexibility of attachment chain allows designers to optimize the same product for multiple configurations, capacities, environments and motions with minimal rework. It consolidates mechanisms down to the chain itself while enabling customization.

Need an attachment chain? Get a fast, competitive quote from the experts at Universal Chains! Contact us now to discuss your requirements.

What Are the Roller Chain Attachment Types?

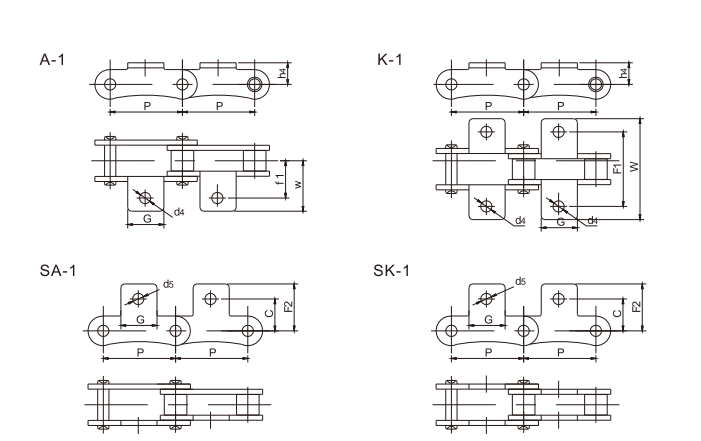

Roller chain attachments take on diverse forms thanks to the flexibility of welding additional features directly onto the inner and outer plates. Here are some of the most common attachment shapes used:

| Roller Chain Attachment Type | Structure | Function |

| Straight Roller Chain Attachment | With a straight extension or tab attached to the chain’s plates, parallel to the chain’s movement | For mounting components such as brackets or crossbars for material handling or conveyor systems |

| Bent Roller Chain Attachment | Features an extension bent at an angle (usually 90 degrees) relative to the chain’s plates | For the side mounting of components, such as conveyor systems and automation |

| Bent-Over Roller Chain Attachment | Related to the bent attachment but with an extra bend, creating a hook-like or U-shaped structure | For gripping, guiding, or lifting materials in conveyor systems, as well as in automated processes |

| Extended Pins Roller Chain Attachment | Features pins extending outward from the chain plates, which are longer than those of standard roller chains | Provides attachment points for sprockets, special fixtures, or guiding mechanisms in conveyors and machinery |

| Wide Contour Roller Chain Attachment | Attributed with a wider-than-standard plate design for increased contact surface and stability | Steps up load distribution and stability, commonly used in heavy-duty conveying applications |

Straight Attachments

As the name suggests, straight attachment plates maintain the native roller chain geometry without bends. They may contain holes, threads, pins and other functional features. Straight attachments can be mounted to one or both chain sides.

Use cases include connection points to other hardware, anchors, guides to constrain the chain, and mechanisms with rotating joints.

Bent Attachments

Bent attachment plates take on L-shapes with 90 degree bends or other angles[1]. Bending the plate itself enables additional functionality like pivoting joints or angled connection points to external hardware.

Holes, threads and other elements can be added as well. Bent attachments see use in articulated mechanisms, guides, and adjustable connections.

Bent Over Attachments

This style bends the plate back on itself to create a hook-like profile. The bent over section may also include holes, threads and other functional elements.

Common uses include attachment points for hooks, rings or other guiding components that redirect chain routing. Bent over attachments also enable secure anchoring.

Extended Pins

Here, standard chain pins get replaced by longer versions that protrude well beyond the outer plates. Extended pins serve as pivots, connection points and supports for auxiliary components.

Use cases include articulated joints for increased flexibility, or mount points for accessories like scrapers, carriers and more. Chains can have extended pins on one or both sides.

Wide Contour Attachments

This broad category entails attachments with larger, wider bent plates contoured to specific shapes beyond simple bends. Wide contour attachments fit around or support other components.

Typical applications include curved guides and guards to direct the chain’s path, integrated scrapers and lubricators, and attachments encompassing other moving parts.

General Attachment Chain Parts and Assembly Parts

To further understand how each of those types works, it is crucial that you get to know their chain parts and assembly parts. Here is a general listing:

Basic Parts

1. Link Plate

Starting off with the link plate. This component is responsible for bearing the tension placed on your chain. Usually, it is of the repeated load type, sometimes accompanied by shock. Thus, this plate must not just have static tensile strength, but must also hold up to the various dynamic forces of load and shock.

2. Pin

Meanwhile, this pin is that part subject to shearing and bending forces that the link plate transmits. Simultaneously, it forms a load-bearing part, together with the brush, the instant the chain flexes when engaging with the sprocket. Thus, it must possess high tensile and shear strength, bending resistance, and sufficient endurance against shock and wear.

3. Bush

Unlike the pin, the bush is subject to the most complex forces from all the other parts, especially when repeating shock loads when your chain gets engaged with the sprocket. It is for this reason the bush must have high shock resistance and wear resistance.

4. Roller

Then, you have the roller, the part subject to impact load as it interacts with the sprocket tooth during engagement. Afterward, it changes its point of contact and balance. Its movement requirements necessitate that it is highly resistant to wear and must have impressive strength against fatigue, shock, and compression.

The other minor basic parts are the roller link, pin link and intermediate plate, and spring clip and cotter pin. The last two sets are often together as one.

Assembly Parts

1. Connecting Links

Connecting links are classified into two types: spring clip and cotter pin. Which of the two would used depends on the size of chains being linked or connected.

2. Offset Links

Meanwhile, this assembly part is used when an odd number of chain links is needed.

Conclusion

Attachment chain unlocks speed, simplicity, and flexibility for industrial designers through integrated useful features. This transforms ordinary roller chain into a versatile assembly component ready for immediate connection and adjustment. By consolidating mechanisms down to the chain itself using welded-on attachments, engineers gain efficiency while enabling customization to the application.

The next time a project calls for adjustable conveying, flexible power transmission, or motion guidance, consider employing attachment chain from Universal Chains as an enabling “backbone” component. The usefulness built right into each link can simplify the entire machine.