Introduction

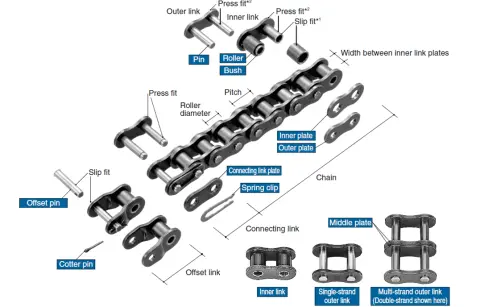

The only noticeable difference between a riveted roller chain and a cotterless roller chain is how the pin is secured. A cotter type chain utilizes a cotter on one end and a staked pin on the other end, while a roller type chain has pins that are staked on both sides. Both types meet the same ANSI B29.1 standards and can work with similar sprockets.

Appreciating these outlines is very essential for industrial purposes because every chain type has varying degrees of profitability where repairs, life rotation, and modifications are concerned. This guide will enable you to select a precise prototype to match your working requirements by comparing the critical parameters, use scope, and service conditions which seek to enhance the efficiency of your business.

Understanding Riveted Roller Chains

Riveted roller chains are said to be the ‘oldest’ and the most common type regarding use in most industrial processes. Riveted pins are fixed on each side of the roller throughout the length of the roller chain. At Universal Chain, quality control from our manufacturing process is achieved by:

- Strict procedural hot treatment methods

- Concentrated and effective administration of advanced machinery

- Rigorous quality control systems

- Extensive tests are performed

Key Features of Riveted Chains:

- The ability to dual or quad stake makes these chains more robust in terms of durability

- Offers good protection in the event of shock loading

- Excellent performance in high-speed applications

- Stronger and more robust

Understanding Cottered Roller Chains

These cottered chains have a unique method of construction as they use flanged cotter pins around one side only, with two-sided staking around the other. This design provides beneficial features for specific uses, such as instances that require frequent metric adjustments.

Notable Characteristics:

- Maintenance and length adjustments are made straightforward

- Slightly wider profile than riveted chains

- Compatible with standard sprockets

- Easier dis-assembly

Manufacturing Excellence at Universal Chain

At the production site of Universal Chain, which operates over 2,000 advanced machines, the company produces riveted and cottered roller chains that meet international quality standards. Assuring customer satisfaction in quality can be seen through:

- ISO9001, ISO14000, and IATF16949 certifications

- Testing equipment available at a higher grade

- Quality measures without loopholes

- Top-notch innovation and creativity within the industry

Technical Comparison and Applications

Manufacturing Standards and Specifications

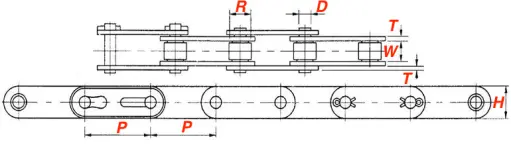

Both the cottered and riveted chains produced at Universal Chain are in compliance with international standards set by ANSI B29.1, ISO, and DIN regulations. The primary dimensional variation is found in the size of the pin, known as the pin, consisting of a cottered/ riveted stock that uses a more extended cotter pin size. Cotter chains have slightly greater pin lengths to accommodate the cotter pins. Our fine manufacturing mechanisms enable us to have close tolerances and uniformity in quality of the two varieties.

Performance Characteristics

The testing facilities of Universal Chain, with 800KN fatigue testing machines and 600KW of wear-testing machines, have established that:

- Riveted chains are best used in:

- High-speed operations

- Continuous High Loads

- High Durability Design Environment

- Cottered chains are optimal for:

- Length changing capacities at arbitrary intervals

- Maintenance type of operations

- Technology requiring fast assembly/disassembly

Industry-Specific Applications

Fifty years of experience in Universal Chains in over 30 industries around the world shows the following where every chain is designed for optimal performance:

Riveted Chains Best Uses:

- Mining and heavy equipment

- Continuous production line

- High-speed machinery processes

- Agricultural machinery

Cottered Chains Best Uses:

- Material handling systems

- Steering control of platforms requiring frequent change

- Devices exerting periodic maintenance

- Prototypes and microtesting

Quality Assurance and Testing

In the company of Universal Chain, each chain is systematically tested by our comprehensive quality control system:

- Raw material verification

- In-process inspections

- End-line finishing controls

- Large assessment/test reports

- Evaluation of defect tolerance

Making the Right Choice for Your Application

Maintenance Considerations

In the comparison of cottered roller chains with riveted chains, maintenance issues must also be considered during the selection processes. Universal Chain’s engineering department advises to consider the following:

- The number of times length changes are likely to take place

- The type of operating environment conditions

- The knowhow training of the maintenance personnel and the tools available for them

- Any expected requirements for the life of the service

Cost-Benefit Analysis

Cost-benefit is essential to many applications and operational requirements, but both chain types give good useful value, but their total cost of ownership will differ for an application. Universal Chain’s history in chain production since 1970 experiences that:

- The upfront establishment expenditure inputs

- Long-term maintenance costs

- Replacement frequency

- The effort (time) and the cost undertaken in the integration phase

Frequently Asked Questions

Which chain type is more durable?

Both types give similar effectiveness when used properly after proper servicing. Continuous running with riveted chains is preferable, while cottered chains are easier to maintain.

Can I switch between riveted and cottered chains?

Yes, both chains can be used on the same sprockets since they both have the same ANSI B29.1 standards.

How do I know which chain type is right for my application?

Contact Universal Chain’s technical team for our detailed experience on case scenarios concerning your operating environment and expectations.

Conclusion

Your maintenance strategy and the working conditions will determine the chain type you will choose among the rivets and the cotters. Rivetted chains are best suited for operations with no self-stopping moments, while cottered chains can be relied on for straightforward maintenance and modification of length.

Need expert guidance for your specific application? Explore our entire collection of industrial chains and speak to our technical team for advice. With more than 50 years of assisting over 30 sectors, we will ensure your selection is right for your operations.