Take a look around any factory floor, farm, or warehouse. Notice how everything keeps moving smoothly? Roller chains are the reason. These hardworking chains power the conveyor belts moving your Amazon packages, the lifts stacking warehouse pallets, and the farm equipment harvesting crops.

At Universal Chain, we’ve been supplying these essential chains to businesses for over 30 years. Let’s walk through what you need to know about choosing and using the right roller chain for your equipment.

What is a Roller Chain?

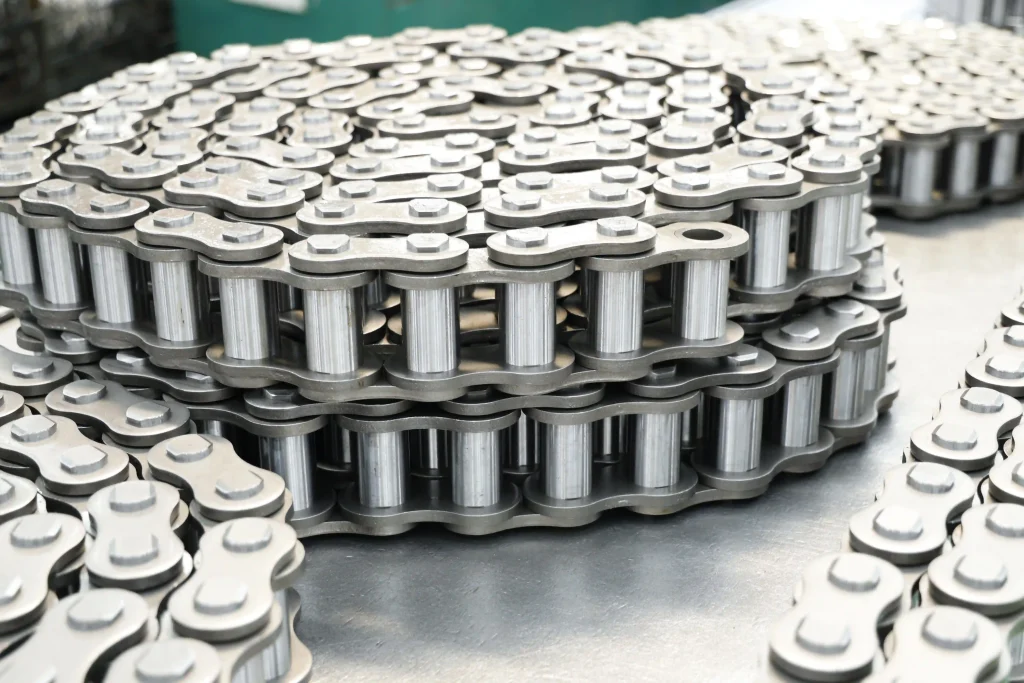

Think of roller chain as the backbone of industrial movement. It’s a type of power transmission chain made up of small cylindrical rollers connected by side links. While that might sound simple, this clever design has been powering everything from tiny garage door openers to massive manufacturing plants for over a century.

How Does it Work?

The key is in how roller chain components interact. The chain’s rollers connect with sprocket teeth while pins and bushings allow smooth movement between links. This simple but effective design transfers power from one sprocket to another, driving everything from small workshop equipment to large industrial machines.

Learn more about the core parts in our detailed guide to roller chain components.

Why Choose Roller Chain?

- Reliable strength: These chains handle heavy loads consistently, making them ideal for industrial applications where dependability matters.

- Efficient power transfer: The design reduces friction and energy loss, providing cost-effective power transmission for your machinery.

- Simple maintenance: Basic care keeps roller chains running well. Regular lubrication and periodic checks are usually all you need.

- Versatile use: With various roller chain sizes available, they suit applications from precision equipment to heavy machinery.

Where You’ll Find Roller Chains

Roller chains keep industry moving in ways you might not expect. From a massive 60-mile conveyor belt carrying phosphates across the Sahara to precision lumber mills guiding logs through processing, these chains handle incredible tasks daily.

Common Applications

Modern operations rely on roller chains for:

- Manufacturing lines: Moving loads up to 15,000 pounds with industrial hoists

- Agricultural equipment: Powering hay balers and material handlers in tough conditions

- Conveyor systems: Using specialized attachments for precise material movement

- Heavy lifting: Double chain configurations handling up to 35,000 pounds

- Assembly lines: Meeting ANSI/ISO standards for consistent performance

Choosing the Right Chain

Getting the right chain matters for your operation. Take the difference between 40 and 41 chains – while both have 0.500 pitch, the 40 chain offers 4,188 pounds of tensile strength compared to the 41’s 2,866 pounds.

Discover all roller chain types and their specific uses

Key Selection Factors:

- Load requirements Consider both maximum and typical operating loads. This determines whether you need single, double, or specialized configurations.

- Operating environment Different conditions demand different solutions. Heat, moisture, dust, and chemical exposure all influence chain selection.

- Speed and cycle time High-speed operations have different needs than slow, heavy-duty applications. Your speed requirements help narrow down suitable options.

- Maintenance considerations Think about access for lubrication and inspection. Some locations might need specialized low-maintenance solutions.

- Cost efficiency Balance initial cost against expected lifespan. Sometimes investing more upfront in better materials saves money long-term.

Want to explore specific chain types for your application? Learn how to measure roller chain accurately to ensure you get the right fit.

Looking at what we haven’t covered yet, let me suggest adding these valuable sections:

Real-World Performance Considerations

Understanding how roller chains perform in actual working conditions helps you make better maintenance decisions.

Even the best chains face challenges like load variations, speed fluctuations, and environmental stresses. Factors like operating temperature, exposure to moisture, and presence of abrasive materials all impact chain life.

For example, in agricultural applications, chains must handle both heavy loads and exposure to crop debris. Manufacturing environments might expose chains to chemical vapors or extreme temperatures.

Each situation requires specific attention to maximize chain performance.

Optimizing Chain Life

Several factors influence how long your roller chain will last:

- Operating Speed: Higher speeds generally mean more frequent maintenance needs

- Load Distribution: Uneven loads accelerate wear in affected areas

- Environmental Protection: Proper guards and seals keep containments away

- Temperature Range: Extreme heat or cold affects lubrication requirements

- Sprocket Condition: Worn sprockets accelerate chain wear

Industry standards like ANSI and ISO help ensure consistent chain performance. These specifications cover everything from manufacturing tolerances to testing procedures. Understanding these standards helps you make informed decisions about chain selection and replacement intervals.

Explore Our Premium Roller Chains – Contact Us Today for Customized Solutions!

Your Trusted Partner in Chain Solutions

At Universal Chain, we know how much your equipment depends on a strong, reliable roller chain. From forklifts to conveyor belts, these chains are what keep things moving—and when they fail, it’s a problem you don’t need.

That’s why we focus on building roller chains that can handle the pressure. With tensile strength 1.2 times higher than ISO 606 standards, they’re built for the kind of heavy lifting and constant use your business demands. It means fewer replacements, less downtime, and one less thing to worry about.

Here’s why businesses in over 100 countries turn to us:

- Tough as Nails

Our chains are designed to stand up to wear, impact, and heavy loads without giving out. - Tailored for Your Needs

Got a specific job in mind? We create solutions for everything from agricultural machinery to construction equipment. - Consistently Reliable

Each chain is tested to the highest standards, so you get consistent performance day after day. - Experienced and Trusted

With over 50 years in the industry and 10,000+ clients, we know how to deliver quality that works.

If you’re dealing with tough conditions, we’ve got chains that can take it. Dusty farm fields? No problem. Heavy machinery at a construction site? Bring it on. We’ve seen it all and built chains to handle it.When your equipment relies on a roller chain that just works, you want a partner that understands what’s at stake. Let’s get your operation running smoothly—contact us today, and we’ll help you find the perfect chain for the job.