Chain testing is critical for ensuring that the chains used in various industries are durable, reliable, and safe. Chains must meet strict standards to perform well under stress. Testing verifies that chains can withstand environmental conditions, heavy loads, and long-term wear.

This blog will explore the most important types of chain testing. We’ll also explain why these tests are necessary and how they help ensure chains, like carbon steel chains, are reliable and fit for their purpose.

Key Chain Tests

Several tests are conducted to evaluate the performance of chains. These tests examine different aspects of the chain’s strength, durability, and resistance to environmental factors. Let’s take a closer look at these critical tests.

Push-Out Force Test

The Push-Out Force Test is designed to check the tightness between the chain’s components. It particularly tests the connection between the outer plate and pin, as well as the inner plate and bush.

If a chain fails this test, it means there’s a risk of pins separating from the outer plates or bushes from the inner plates during operation. This can cause serious operational issues and even lead to chain failure.

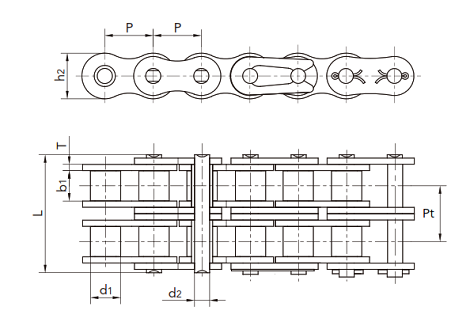

Chain Length Measurement

Accurate chain length is essential for proper operation. If a chain is too long or too short, it may not fit the sprocket correctly, causing noise or improper functioning. The Length Measurement Test ensures that the chain pitch— the distance between the pins— is within the standard tolerance.

For instance, the standard pitch for an ANSI 80 chain is 25.4 mm. Due to manufacturing tolerances, slight variations in each plate’s pitch may occur. But, the chain length must still fall within acceptable limits to ensure it works smoothly with the sprocket.

Pre-Stretching (Pre-Loading)

Once assembled, chains are subjected to a process called pre-stretching. This is where an initial load is applied to the chain to tighten its components. This process helps reduce the chain’s initial wear when it is first used in a machine.

Applying an initial load, usually one-third of the breaking load, helps the chain components fit more tightly. This improves the chain’s durability and tensile strength.

Salt Spray Test Standard

It is essential for evaluating the corrosion resistance of chains. In this test, the chain is exposed to a 5% salt water spray in a controlled environment, following the ASME B117 standard. The test measures how long it takes for rust to form on the chain.

Chains that pass this test are better suited for harsh environments where they are exposed to moisture and corrosive substances. This ensures long-lasting performance in such conditions.

Wearing Test

This test evaluates the wear resistance and durability of a chain over time. Chains are subjected to repetitive motion similar to what they would experience during normal operation. This is to see how long they can maintain their performance before showing signs of wear.

Currently, there are no universal standards for chain wear testing. However, the Japan Chain Association (JCAS) has established wear-testing guidelines for motorcycle chains. Manufacturers may have different methods for wear testing. So, results can vary across different companies.

Ultimate Strength Test (Chain Tensile Strength Test)

This is also known as the Chain Tensile Strength Test. It measures the chain’s ability to withstand maximum force before breaking. This test is crucial for ensuring the chain can handle the loads it is designed for without failing under stress.

The test follows ASTM standards for tensile testing. The results help identify any issues in the chain’s production. Examples are poor heat treatment or missing components, which could lower the chain’s strength. If the chain breaks below the set standard, it indicates a problem that could compromise safety and performance.

Fatigue Test

This test is perhaps the most important test for determining a chain’s long-term durability. This test measures how much repetitive stress a chain can endure without breaking. The chain is subjected to repeated loads to simulate real-world use. The test determines the maximum tensile load that the chain can withstand without failure over time.

The Fatigue Test gives a more accurate representation of a chain’s performance in actual working conditions. Compared to the Ultimate Strength Test, which focuses more on the chain’s maximum load capacity in a single instance. Fatigue strength is a critical factor for chains used in continuous or high-stress applications.

While both ultimate strength and fatigue strength are important, they are not always directly correlated. A chain with high fatigue strength may not have a very high ultimate strength, and vice versa. This is why both tests are essential for a complete picture of chain quality.

Why Choose Universal Chain?

When it comes to chain manufacturing, Universal Chain is a leader in quality and innovation. They incorporate cutting-edge research, manufacturing processes, and rigorous testing to ensure their products meet the highest standards.

Advantage of Research & Development

Universal Chain focus on research and development is backed by its National Enterprise Technology Center. They set industry standards with over 100 patents. They continually advance the field of chain manufacturing.

Advantage of Manufacturing

They have over 2000 high-precision production machines and 6 unique processing techniques. Universal Chain ensures every chain is made with exact precision and superior quality. Their intelligent production management system guarantees consistency and efficiency.

Advantages of Quality Control

Universal Chain takes quality control seriously. They use large tonnage testing equipment to conduct thorough inspections on every product. They have strict quality control regulations and a product traceability system. This ensures each chain meets high performance and safety standards.

Conclusion

Chain testing is essential for ensuring that the chains you use are durable, safe, and suited to their intended application. Tests provide critical data about a chain’s strength, wear resistance, and corrosion protection. Additionally, ASTM standards for tensile testing help verify that chains can withstand maximum loads without failure.

Universal Chain stands out in the industry with its commitment to quality, precision, and innovation. They use rigorous chain testing and top-quality manufacturing processes. This ensures their chains provide long-lasting performance, even in tough conditions.