Introduction

Roller chains should be changed if the percentage of elongation is more than 1.5 or if there are observable signs of wear on the chain. These flaws should be watched regularly to preempt emergencies that lead to expensive breakdowns of equipment and loss of time.

Realizing when one needs to change their roller chain is vital for smooth functioning and safety. This guide outlines the various indicators, procedures, and expert practice that enable you to make changes to your chain maintenance schedule based on informed wisdom.

Key Signs Your Roller Chain Needs Replacement

1. Excessive Chain Elongation

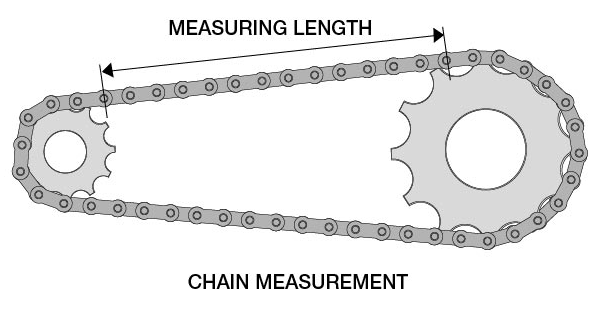

This stretch of the chain is the most reliable indicator of joint wear over time. When a roller chain has two ends, and the distance between them stretches too much, corrective measures are needed:

- Measure chain elongation regularly using a caliper

- For most applications, 0.8%-1.5 percent elongation means it is time to replace the chain.

- Consider changing the chain if elongation has reached up to 3 percent.

2. Visual Wear Indicators

Usually, preventative measures will be possible if these or other similar features are present: the structural elements are worn through or cracked:

- Roller surfaces that have cracking or signs of wear

- Bushing wear, which is visible

- Loose and worn pins

- Corrosion and rust.

3. Performance Issues

Typical malfunction warning signs include the following:

- Unusual noise during operation

- Unusual vibration

- Frequent chain binding

- Tension is still lost with frequent readjustments of the system.

Why Choose Universal Chain for Replacement

Universal Chain can rightfully consider itself one of the leaders among chain transmission manufacturers, producing about 60 million meters of chain per year. The guarantee for quality here is provided by:

- High technological capability, over 2000 sets of production equipment

- Complex and appropriate measures and instruments of quality assurance

- Recognized management system including ISO9001, ISO14000, and IATF16949

- Custom solutions with specialized engineering skills.

Proper Maintenance and Measurement Procedures

How to Measure Chain Wear Accurately

A systematic approach to chain wear measurement is recommended by Universal Chain. Here is the professional method:

- Use a precision caliper to measure between the pins

- The goal is to take several readings from several different locations.

- Work out the mean elongation percentage from your observations.

- Final values should be noted for future reference.

Related Reading: How to Measure Chain Size

Professional Maintenance Tips

For a longer life of your roller chain, the engineering team at Universal Chain recommends the following essential maintenance activities:

- Lubrication with suitable grade oil at regular intervals.

- Proper chain tension is maintained to avoid excessive sag (approx. 2–4 percent).

- Clean the chain regularly to prevent debris build-up

- Sprocket alignment should be regularly reinforced.

Related Reading: Roller Chain Installation and Maintenance

Understanding Chain Types and Applications

Every application calls for using a particular chain type. Universal Chain provides several solutions, including:

- The 2040 roller chain is for general-type machinery and industrial applications.

- Heavier, high-strength replacement drives for chain assemblies.

- Corrosion-resistant chains that can withstand adverse conditions.

- Solutions specially designed to meet the demands of the industry.

Quality Assurance and Testing

The quality assurance plan of Universal Chain incorporates:

- Comprehensive testing processes using modern equipment

- 800 kilo-newtons in fatigue testing

- A fully fledged quality management system

- ISO-level processes for success of manufacturing

Expert Consultation Services

With nearly 50 years in the business, Universal Chain offers:

- Chain system posting guidelines

- Provision of developed solutions to clients’ problems

- Installation of the equipment

- Advice on maintenance practices

Making the Right Choice for Chain Replacement

Frequently Asked Questions

How often should I replace my roller chain?

Wear varies with usage. Universal chains would suggest replacement when the elongation is more than 1.5 percent usually or even before this if signs of visual wear have been seen.

Can I replace just the chain without the sprockets?

Both elements should be replaced, in the opinion of Universal Chain to maintain optimum performance and to avoid early deterioration.

What makes Universal Chain different from other manufacturers?

More than half a century of experience, which includes capitalization of ISO good manufacturing and so far passive production capacity of over 60 million meters per annum. Universal Chain stands out in terms of quality and support.

Conclusion

Do not let your roller chain fail before you replace it – check for elongation and other wear indicator factors as necessary. With the right strategies and controls in place, the cost of maintaining systems and chains can be brought down and surprise failures avoided.

You can, however, be sure to get the best roller chain that fits your specifications by going to Universal Chain for killer products and the best technical support. Our assessments are structured to ensure that you and every other customer is satisfied with what they need to replace the chain there and then.