The foundation of Industrial Automation and Manufacturing Processes is based on mechanical power transmission products. Mechanically, devices like chains or drives are utilized to transfer energy and motion efficiently. This allows various industries to continue operating throughout the world today. However, as Universal Chain has done for the last half a century, they stand for developments in the quality production of power transmission products. Today’s universal chain is definitely capable of turning heads even in the fastest-changing industries.

The market for mechanical power transmission is predicted to grow rapidly, rising from 32.56 billion U.S. dollars in 2017 to 67.48 billion U.S. dollars in 2023 with a compound annual growth rate of 8.5 percent. This growth is largely fueled by a rise in market employment throughout many sectors, including manufacturing, forestry, and agriculture, Thanks to rapidly developing automation technology.

Understanding Mechanical Power Transmission

What Are Mechanical Power Transmission Products?

Mechanical power transmission products include a variety of components that are crucial for transferring power and torque from the source of power, towards the driven components. These systems find usefulness in:

- Industrial machinery and processes of manufacturing

- Automotive and aerospace applications

- Agricultural and construction machinery

- Systems of material handling

- Generation and distribution of energy

Core Components and Their Functions

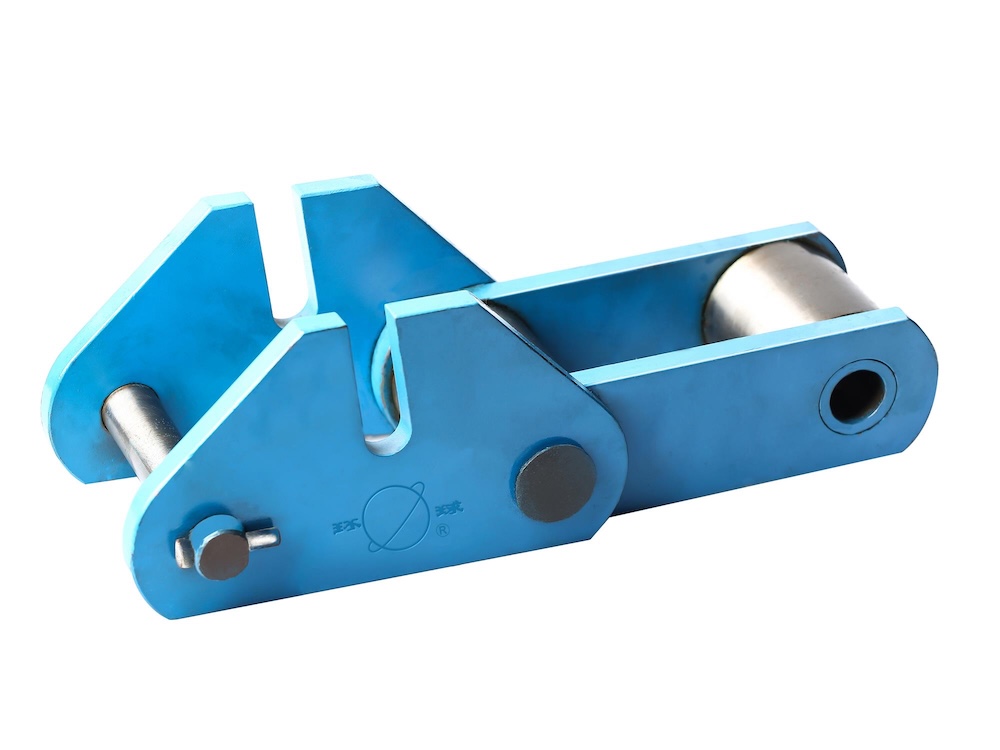

- Chain Systems

Universal Chain, recalled in 1970, has become a front-runner in manufacturing chains suitable for use in chain transmission systems, producing more than 60 million meters of chains a year. The following chains were among the products that supported this:

- Rollers chains, which are very precise for industrial use

- Chains that are designed for heavy engineering work

- Chains that are conveyor chains used in material handling

- Chains that are specialized for industrial use

- Power Transmission Devices

- Drive belt drives

- Gear systems and gears

- Bushings and bearings

- Couplings and clutches

Industry Leadership and Innovation

The unquestioned leadership of the industry UC manifests itself in such aspects as:

- Advanced manufacturing capabilities with 2000+ sets of production equipment

- Certifications: ISO9001, ISO14001, ISO45001, IATF16949

- Integrated IT-enabled systems for effective quality management

- Development in research and development infrastructure

Market Trends and Technological Advancements

Mechanical power transmission is undergoing great changes due to great ideas:

- Digital approach for improved efficiency and quick access

- Cost-and-energy-effective Solutions for Green Future

- Making of green parts

- Development of intelligent monitoring systems

Advanced Applications and Technical Specifications

Innovative Chain Solutions for Modern Industries

Universal Chain’s promise to innovate can be seen in the comprehensive range of specialized products. Their advanced manufacturing facility, equipped with more than 2000 sets of high-precision equipment, builds chains for different industrial needs. The company offers:

Precision Roller Chains

The precision roller chains offered by Universal Chain consist of:

- Better Wear-Resistant Materials

- High Manufacturing Precision

- International Organization for Standardization (ISO), DIN, ASME/ANSI

- Added strength for harsh running conditions

Engineering Class Chains

These are chains, which can be applied to:

- Heavy-duty mining operations

- Construction machinery

- Agricultural machinery

- Material handling systems

Quality Control and Certification

Universal Chain has very high quality control in processes and products with the help of:

- Fully established and equipped testing centers with over 50 machines for testing various parameters

- Quality information systems for tracking products through the facilities

- Numerous certifications including:

- ISO9001 for quality management

- ISO14001 for environmental standards

- IATF16949 for automotive industry requirements

Digital Integration and Smart Manufacturing

This challenge can also be met through the company:

Intelligent Production Management

- Monitoring of production processes in real-time

- Self-operating quality control networks

- Digital inventory management

- Integrated supply chain solutions

Research and Development

The development of new technologies at the National Enterprise Technology Center of Universal Chain is directed towards:

- Research and development of new materials

- New technologies for processes

- Testing and evaluation of the products

- Research work in cooperation with universities

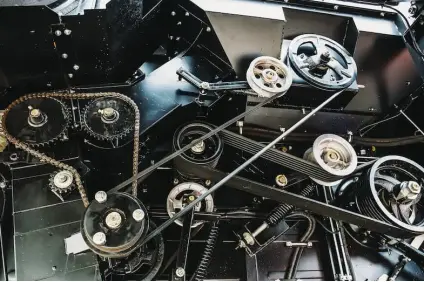

Industry Applications and Solutions

Universal Chain’s products are used in multiple industries:

Industrial Manufacturing

- Systems of conveyors

- Processing equipment

- Packaging machinery

Construction and Mining

- Large machines

- Material handling

- Machinery for excavation

Agricultural Equipment

- Machines for harvesting

- Models for irrigation

- Models for irrigation

Automotive and Transportation

- Systems of engine timing

- Applications of conveyor systems

- Mechanisms of non-moving drive systems

The Evolution of Power Transmission Technology

The development of the industry of power transmission is in active change because of the introduction of new technologies as well as the emergent needs of the market. Industry analysts also expect strong growth in the market, even beyond the year 2024. The company Universal Chain has been, and continues to be, at the center of this development, creating innovative approaches and solutions for the development of this sphere.

Emerging Technologies and Innovation

One can appreciate Universal Chain’s devotion to innovation through their elaborate research and development efforts. Their National Enterprise Technology Center joins forces with high-profile universities and research centers to provide advanced power transmission technologies. The firm’s emphasis on the application of technological capabilities for digital integration and smart manufacturing technologies places them at the forefront of Industry 4.0 implementation.

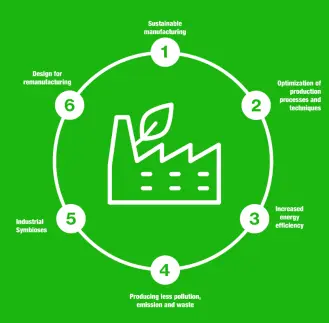

Sustainability and Environmental Considerations

There is an increasing trend towards developing modern power transmission solutions without compromising on environmental impact. This dedication by Universal Chain is demonstrated through:

- Implementation of eco-friendly manufacturing processes

- Create energy-efficient products

- Use of green materials and practices

- Adherence to global environmental regulations

Maintenance and Optimization

It is in the design of Universal Chain products to provide high efficiency and long-period of failure-free operation. The comprehensive quality control system of the company, which comprises over 50 sets of inspection equipment, ensures dependable operation and low maintenance requirements. The firm’s ability to track products digitally allows for timely monitoring and scheduling of maintenance activities.

Frequently Asked Questions

What makes Universal Chain different from other manufacturers?

With over 50 years of expertise, Universal Chain uses modern technology and produces 60 million meters of chains a year with high quality and international standard certification.

How does Universal Chain ensure product quality?

The level of quality is ensured through comprehensive testing facilities, advanced quality traceability systems, and several international certifications, namely ISO9001, ISO14001, and IATF16949.

What industries does Universal Chain serve?

The target industries for Universal Chain include but are not limited to industrial, manufacturing, construction, mining, farming, and automobile industries.

Conclusion

Innovation, sustainability, and digitalization will define the future of mechanical power transmission. In this dynamic environment, Universal Chain endeavors towards excellence, which is evident from the in-house modern manufacturing facilities and the effective quality management systems they operate. Moreover, their ongoing projects in research and development, as well as their ecological concern, guarantee that they will remain active in any industrial progress.

As industries advance and require more advanced power transmission solutions, there is no other company than Universal Chain that manufactures and delivers quality, innovative power transmission products while providing utmost services to clients and their customers. Their extensive spectrum of solutions, reinforced by worldwide recognition and years of practice, keeps developing and enhancing the possibilities in the field of industrial energy transmission.