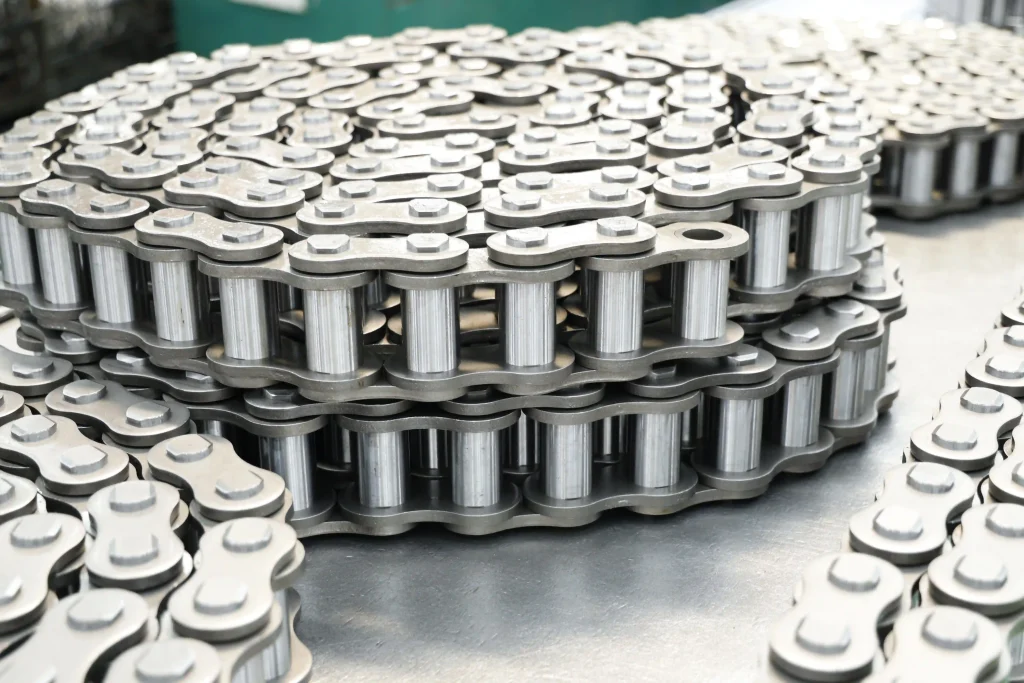

Roller chains are essential in various industries. They provide a reliable and efficient method for transmitting mechanical power.

However, over time, chain elongation—commonly known as chain stretch—can occur, leading to decreased efficiency and eventual failure. Understanding how to prevent roller chain wear and elongation is crucial for ensuring long-lasting performance and minimizing downtime.

In this article, we’ll explore what causes chain elongation and provide actionable tips to prevent it, ensuring your chains remain in optimal condition for extended use.

What Causes Chain Elongation?

Chain elongation, or chain stretch, is a natural result of wear and tear on a roller chain. It’s important to note that chains do not physically stretch; rather, the elongation occurs due to the wear between the chain’s pin and bushing, causing them to lengthen over time. This wear increases the distance between the links, leading to poor engagement with sprockets and eventual malfunction.

What causes chain elongation? Chain elongation is caused by:

- Insufficient lubrication

- Overloading

- Environmental factors

- Misalignment

Insufficient Lubrication

Proper lubrication is critical to reducing friction between chain components. Without adequate lubrication, the pins, bushings, and rollers are exposed to excessive friction, leading to accelerated wear.

Overloading

Chains designed for specific loads can become over-stressed if they are used in situations that exceed their load capacity. Over time, this causes excessive pressure on the chain’s components, contributing to faster elongation.

Environmental Factors

Exposure to harsh conditions such as dust, moisture, chemicals, and extreme temperatures can degrade chain material. These environmental factors cause corrosion, rust, and additional friction, all of which contribute to wear and elongation.

Misalignment

If the chain is not aligned properly with the sprockets, uneven load distribution can occur, accelerating wear on specific sections of the chain. This eventually leads to uneven elongation and inefficient performance.

Tips to Prevent Roller Chain Elongation

To maximize the lifespan of your roller chains and prevent elongation, it’s important to implement regular maintenance and best practices. Here are some expert tips:

- Ensure Proper Lubrication

Lubrication is essential for minimizing friction and wear between the chain’s moving parts. By applying the right lubricant, you can create a protective film that reduces metal-to-metal contact.

Opt for a lubricant that is specifically designed for roller chains, and be sure to reapply as needed based on environmental factors and operating conditions. Regular lubrication will significantly reduce the risk of chain elongation caused by friction.

- Monitor and Control Load

Overloading your chain can drastically shorten its lifespan. Always ensure that the load carried by your chain does not exceed its design specifications. Regularly inspect the load distribution to prevent excessive pressure on individual chain links. If necessary, consider upgrading to a higher-capacity chain for heavy-duty applications.

- Maintain Sprocket Alignment

Chain elongation can be accelerated by poor alignment between the chain and sprockets. Misalignment increases stress on specific chain sections, leading to uneven wear. Regularly check that the sprockets are aligned correctly, and inspect them for wear or damage that could affect the chain’s performance.

- Select High-Quality Chains

Not all roller chains are created equal. Chains made from high-grade materials are more resistant to wear and elongation, especially when operating in harsh environments. Investing in high-quality chains designed for your specific application can significantly reduce the risk of premature elongation.

- Regularly Inspect Chains

Routine inspections are crucial to preventing chain elongation. By regularly checking the chain for signs of wear, corrosion, or other damage, you can detect and address issues before they become severe. Replace any worn or damaged chains immediately to avoid excessive downtime and costly repairs.

- Implement a Chain Tensioning System

Proper tensioning ensures that the chain is operating at its optimal performance level. A chain that is too loose or too tight can lead to uneven load distribution and accelerated wear. Consider installing a chain tensioning system to maintain consistent tension, thereby preventing elongation.

- Use Chain Guides

Chain guides are designed to support and align chains, reducing the risk of misalignment and excessive wear. By using guides, you can prevent chains from derailing or becoming misaligned, which in turn minimizes the risk of elongation.

Ready to Optimize Your Roller Chains?

Preventing chain elongation requires proper maintenance, high-quality materials, and regular inspections. If you’re looking for a reliable and durable roller chain solution, Universal Chain is here to help.

Our expert team can guide you through selecting the right chain for your application, ensuring maximum performance and longevity. Contact us today to discuss your chain transmission needs, and let us help you optimize your operations.