Introduction

Roll-chain technology seems to have existed with us, and as most modern machinery today will require its use, its definitional attributes and structures are common knowledge that needs to be held by every engineer and technician. This guide will take you through the detailed definitions and technical features of the chain technology as applicable in the industrial environment.

The never-ending search for answers will cause some frustration for the chain of technology. In this guide, you will use what you have learned in the last 50 years from Universal Chain about chain manufacturing to locate various roller chain types and their pieces and their applications.

Key Components and Terminology

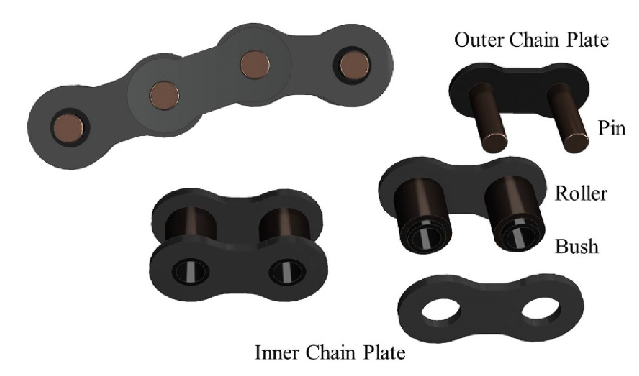

Roller chain technology is based on sprockets, main links, chain pins, chain plates, bushings, and rollers. These parts work together to ensure smooth operation of the chain:

- Basic Components:

- Pin Link (Outer Link): It consists of two pin-link plates and two pins.

- Roller Link (Inner Link): It includes two roller link plates, two bushings, and two rollers.

- Connecting Links: Made in spring clip and tottered styles for various uses.

- Essential Measurements:

- Chain Pitch: The space between the pin centers, necessary for chain sizing.

- Roller Diameter: Influences the Chain’s engagement with the sprockets.

- Inner Width: Important for the right fitting and the proper use.

Universal Chain’s Advanced Manufacturing Process

Universal Chain distinguishes itself through:

- Equipped with advanced production facilities with over 2000 sets of equipment

- ISO9001, ISO14000, and IATF16949 certified with strict quality control systems.

- High-tech solutions to guarantee uniform quality and accuracy.

- 800KN fatigue testing machines with a good range of testing services.

Types of Roller Chains

When it comes to roller chains, Universal Chain offers the following types suited for various tasks:

- Simple Precision Roller Chains

- Double-Pitch Transmission Chain Systems

- Standard compelling short-pitch precision chains

- Self-Lubricating Roller Chains

- Corrosion-Resistant Chains

Certain standards have been adopted locally and internationally in the production of each type to achieve maximum efficiency in specific tasks.

Advanced Chain Technology and Applications

Manufacturing Excellence and Quality Control

Universal Chain has implemented a unique approach to forming chains based on modern technologies and can produce the amazing chains in the image below. Their most advanced production facility integrates six cutting-edge technologies into the chain production process:

- Chain plate extrusion enhancement

- Automated image detection capabilities

- Preloading will offer a continuous service

- Heat treatment precision

- Laser-cutting, high quality

The firm has a digital integration system that connects every 3 minutes, allowing quality management of production activities without panic.

Industry Applications and Specializations

Universal Chain’s products serve numerous industries:

Heavy-Duty Applications

- Mining and Construction Machinery

- Agricultural Machinery

- Industrial Facilities

- Material Management Systems

Specialized Solutions

- API Spec 7F certified oilfield chains

- Chains that are resistant to corrosion even in hostile environments

- Chains that are self-lubricating to eliminate maintenance

- Solutions that have been specifically designed to fit in particular industrial settings

Quality Assurance and Testing

Universal Chain has in place strict quality control by way of:

- 16 inspection regulations for all raw materials coming in

- Over 800KN machine fatigue tests as part of overload tests

- Advanced quality traceability systems

- ISO9001, ISO14000, IATF16949 international certificates

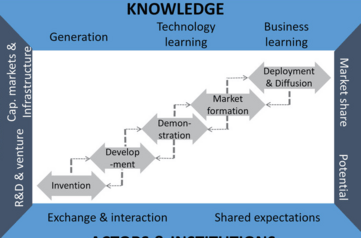

Innovation and Research

Continuous innovation is spearheaded by the company’s National Enterprise Technology Center through:

- Partnership with research universities and institutions

- New technologies for chains production

- Designing of customized solutions

- Testing and developing of new materials

Quality Assurance and Support

Thanks to more than 50 years of experience and international certificates, Universal Chain can guarantee:

- Effective quality management from source materials to end products

- Consulting and customization

- Global distribution network

- Robust warranty protection

Applications, Selection Guide, and Industry Solutions

Frequently Asked Questions

What is chain pitch and why is it important?

Chain pitch represents the distance between the centers of the two side links, removing uncertainty as to the size of the chain. Universal Chain makes chains for users with Universality of Chains in mind.

How do I choose the right roller chain for my application?

Similarly, other parameters like load capacity, working temperature, and maintenance of the system should also be considered. If you require assistance, the engineering team at Universal Chain can help you in selecting the chain that will work best with your specific application.

What maintenance is required for roller chains?

Lack of maintenance such as regular checks and lubrication is not recommended, however Universal Chain has a range of products which are self-lubricating for low maintenance in particular working conditions.

Conclusion

It is important that the right roller chain is selected for machinery to obtain the best results. Your search for chains will also begin with an understanding of terms associated with chains. For custom orders and other support services, please search Universal Chain’s website to have a look at all types of industrial chains available.

Do you wish to learn more about chain technology? For further elaboration on chain technology, you can also refer to Universal Chain at www.universalchain.net where you can use the detailed specifications and application guides to assist you in contacting the experts.