Introduction

The only distinction that exists between a #40 and a #41 roller chain is their inner plate width, which for #40 is 0.312 inches while that of #41 is 0.25 inches. This one difference determines their best use cases, wherein #40 is for heavy-duty while #41 is for precision.

In this article, we shall be highlighting the differences that exist between these two roller chain types by looking closely into their attributes, performance, and most appropriate applications, among other factors. With the help of information available, whether one is focused on heavy industrial machinery and equipment or is working on a precision-turning machine, this information will assist in making a correct choice depending on the required configuration. We also pay consideration to other significant factors such as durability, maintenance, and cost, to present the appropriate chain for the given purpose.

Understanding the Basics

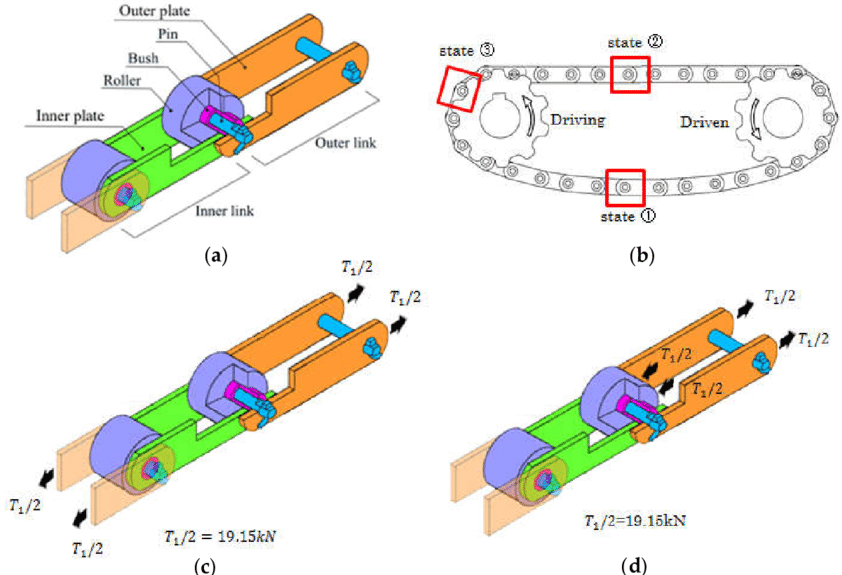

While both the chains have a common pitch of 0.5 inches, the #40 and #41 roller chains have more differences than similarities. For high duty cycles, the #40 roller chain has bi-metal inner and outer plates with larger diameter rollers, increasing its strength and robustness. On the other hand, it has a lower profile shaft diameter, making the #41 roller chain a more convenient option for less demanding applications.

Key Specifications:

#40 Roller Chain:

- Pitch: 0.5 inches

- Width between inner plates: 0.312 inches

- With higher tensile load bearing capacity

- Bigger diameter of the roller

- Improved durability

#41 Roller Chain:

- Pitch: 0.5 inches

- Width between inner plates: 0.25 inches

- Further lightweight construction

- Smaller dimensions for the roller

- Designed to be more compact

At Universal Chain, one may find reasonable assurance that both types of chains are produced with high quality, Thanks to modern equipment and strict adherence to quality control methods. We produce 60 million meters of chains yearly, which clearly demonstrates the ability of non-standard solutions to industrial challenges and have never compromised on quality.

Manufacturing Excellence

Quality is intrinsic to Universal Chain as more than 2000 sets of modern production capabilities are housed in Universal Chain’s quality-controlled factories. Strict quality management systems are applied to all of our roller chains, such as:

- Material structure testing

- Using technology modules such as heat treatment

- Mold shape and size control

- Performance measurement systems

- The company’s production processes have been certified to ISO9001, ISO 14000, IATF 16949

Performance and Applications

Through many years of combining chains and manufacturing a #40 and a #41 roller chain, Universal Chain has witnessed where each of them performs better at which applications. Our highly developed testing equipment, such as the 800KN fatigue testing machines and 600KW wear-testing machines, enable us to assess chain effectiveness thoroughly and accurately across many scenarios.

Load Capacity and Durability

Due to its strong construction, the #40 roller chain is primarily suitable for tough industrial operations. The additional outer plate with a width of 0.312 inches helps in strength distribution and therefore makes it perfect for:

- Heavy machinery operations

- Agricultural equipment

- Industrial conveyor systems

- Mining applications

- Construction equipment

Precision and Efficiency

Also, the #41 roller chain has the same 0.5 inch pitch, but is better for some applications and these applications are designed by Universal Chain for the #41 model. Universal chain created the following:

- Light to medium-duty operations

- High-speed applications

- Small-space applications

- Economic applications

- Precision machinery

Quality Assurance and Testing

Universal Chain ensures that its competitive advantage does not rest solely on its marketing activities by establishing its own advanced quality control system. Each chain is subjected to the following tests:

- Raw Material Verification

- Analyzing steel composition

- Hardness evaluation

- Dimensional accuracy check

- Manufacturing Process Control

- Automated monitoring of the production process

- Quality control during production

- Advanced heat treatment control

- Final Product Testing

- Testing of breaking load

- Testing of fatigue limit

- Testing wear resistance

Industry Applications and Solutions

Universal Chain has been in business for over five decades and has serviced more than 30 industries. For these industries, Universal Chain has created specific applications:

#40 Chain Applications:

- Industrial equipment

- Heavy conveyor systems

- Agricultural equipment

- Mining

- Building equipment

#41 Chain Applications:

- Light manufacturing

- Packaging machinery

- Food industry machine

- Textile machinery

- Small conveyors

Making the Right Choice

A number of considerations should help you decide whether to use #40 or #41 roller chains. In our experience of over 50 years at Universal Chain, we have come to appreciate that the best alternative is dependent on your application details, working environment, and requirements for the performance to be achieved.

Frequently Asked Questions

Which chain is better for heavy-duty applications?

When it comes to strenuous applications, the #40 roller chain is preferred due to its inner plate width (0.312 inches) which is wider relative to the others, as well as its tensile strength. The #40 roller chain produced by Universal Chain is highly durable owing to modern manufacturing techniques.

When should I choose a #41 roller chain?

If you need a lightweight, compact, and inexpensive option, consider a #41 roller chain. It works best with precision machinery and where there are a lot of limitations in terms of space.

Conclusion

When looking at roller chains, make sure to select #40 roller chains on account of its supreme strength for heavy, industrial applications, while #41 roller chains are applicable for lighter, more precise work with space constraints. It’s all about the parameters and conditions of the specific application where the chains will find employment.

How about searching for the very best choice of roller chain in terms of your application? Take a look at Universal Chain for details and the help of the professionals. Our complete resources section also contains technical instructions and recommendations for sizing and maintenance, enabling you to choose the most appropriate option. For more technical data and general industry standards, visit or look at our roller chain resources or consult our engineers for professional advice.