In industrial settings, selecting the right chain is crucial for efficient operation. Among the various materials available, stainless steel roller chains are becoming the preferred choice. Whether in food processing, manufacturing, or other fields, a stainless steel chain can significantly impact performance.

But why are stainless steel roller chains the best choice? Keep on reading to find out.

Corrosion Resistance for Long-lasting Performance

One major advantage of stainless steel roller chains is their corrosion resistance. Unlike regular carbon steel chains, stainless steel chains do not rust or deteriorate. This makes them suitable for:

- Moisture exposure, such as in marine applications and food processing facilities

- Chemical exposure, common in the pharmaceutical and chemical processing industries

- Outdoor environments, where chains face rain, humidity, or extreme temperatures

A 316 stainless chain offers superior resistance to chemical corrosion. This is applicable even in acidic environments. The mentioned durability leads to lower maintenance costs.

Moreover, it implies a longer lifespan for the stainless chain. Overall, stainless steel chains are a cost-effective solution.

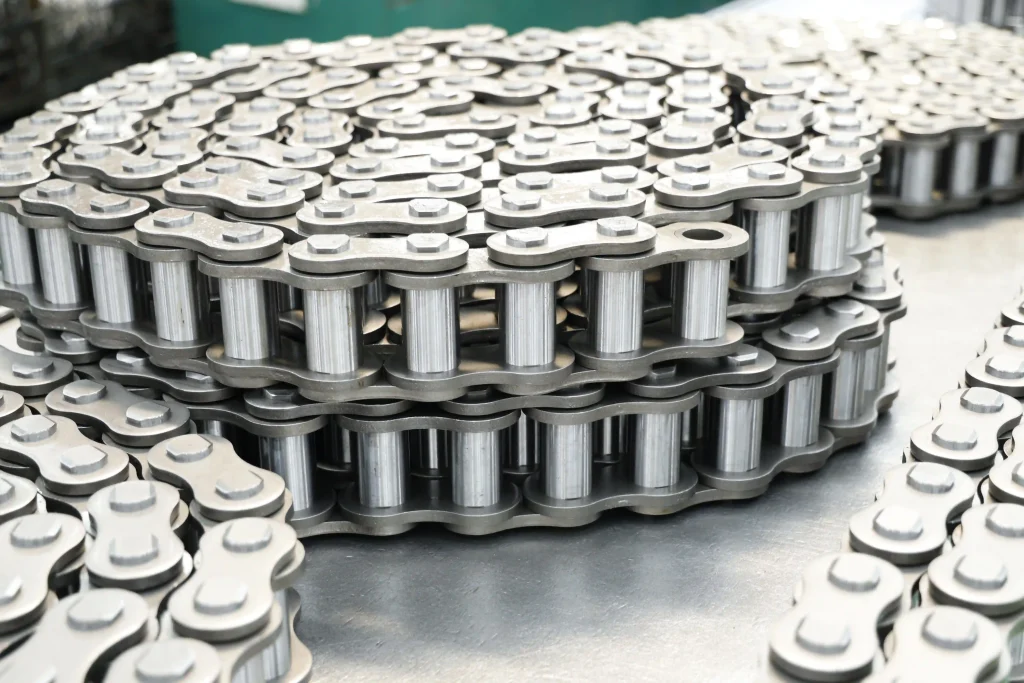

Heavy-Duty Stainless Steel Chains for Robust Applications

For applications that demand strength, heavy-duty stainless steel chains are essential. They are popular for withstanding extreme loads. This is done without even compromising performance. Stainless steel chains are perfect for heavy machinery, construction, and other industrial uses.

Sectors like mining, agriculture, and manufacturing benefit greatly from SS chain. These specialized chains support heavy loads while resisting wear and tear. Additionally, they can perform well under harsh conditions. From extreme temperatures to abrasive materials, SS chains are reliable.

Universal Chain offers various heavy-duty stainless steel chains, making them a go-to supplier for industries that need durable and reliable solutions.

The Versatility of Stainless Steel Roller Chains Across Industries

Stainless steel roller chains are incredibly versatile. For such quality, they are utilized in food production lines and even marine applications. The best part is that these chains excel in diverse environments.2 Their durability and performance make this possible.

Here are some key industries where stainless steel roller chains thrive:

- Food and Beverage Processing

In the food and beverage industry, hygiene is crucial. Stainless steel roller chains are naturally resistant to bacteria. Plus, they are easy to clean. The 316 stainless steel chains even resist corrosion. This quality enables the chains to tolerate moisture and cleaning chemicals.

- Marine Applications

SS chains are widely used in marine environments due to their rust and corrosion resistance. They have become a staple in shipyards, marine equipment, and coastal construction. This is because SS chains can ensure reliability even in highly corrosive conditions.

- Chemical and Pharmaceutical Industries

In chemical and pharmaceutical industries, exposure to acids and alkalis is common. Regular chains can degrade quickly. This could lead to frequent replacements. Stainless steel chains, especially 316 stainless steel chains, resist chemicals. Moreover, they ensure long-term functionality in harsh environments.

- Outdoor and Construction Applications

Stainless steel roller chains are perfect for outdoor use. They withstand exposure to the elements while maintaining strength and longevity. Whether in construction or outdoor facilities, their corrosion resistance ensures reliable performance. These chains perform well amid rain, snow, or extreme heat.

Maintenance Tips for Stainless Steel Roller Chains

Stainless steel roller chains are durable and require less maintenance. However, regular upkeep is essential for optimal performance. Here are some best practices to keep your chains in top condition:

- Lubrication

Lubrication reduces friction and ensures smooth operation. Proper lubrication extends the chain’s life. Inspect and lubricate the chains frequently. Chains in high-load situations may need more attention. Too much lubricant can attract dirt. Apply just enough to coat the surface lightly.

- Inspect for Wear and Tear

Inspect the chain for wear, elongation, cracks, or corrosion. Check the sprockets as well; wear on them may indicate chain problems.

Ensure the chain is properly tensioned. A loose chain can slip off. On the other hand, a tight chain can wear out quickly.

- Replace Worn Components

Use high-quality parts from reputable suppliers like Universal Chain. Stick to the manufacturer’s recommendations for replacements to maintain performance.

By following these maintenance practices, you can ensure that your stainless steel roller chains operate efficiently. Most importantly, they continue to deliver reliable service in various applications.

The Long-term Value of Stainless Steel Roller Chains

While stainless steel roller chains may have a higher initial cost compared to carbon steel chains, the long-term benefits far outweigh the price difference. Remember that steel roller chains offer the following:

- Corrosion resistance

- Strength

- Durability

- Low maintenance requirements

Stainless Steel Chain Suppliers: Why Universal Chain Stands Out

When sourcing stainless steel roller chains, the supplier choice is critical. Universal Chain is a leading manufacturer known for its quality and customer satisfaction. Here are several reasons why Universal Chain is a top choice:

- Extensive Global Outreach

Universal Chain exports to over 100 countries. They have built a strong reputation as a trusted supplier worldwide. Their products serve a wide range of industries. Moreover, more than 10,000 clients have relied on Universal Chain.

- A Legacy of Excellence

With over 50 years of experience, Universal Chain has become a top chain transmission manufacturer. Their team includes over 1,000 employees committed to quality and performance.

- Advanced Manufacturing Capabilities

Universal Chain operates with 2,000 sets of advanced production equipment. This capacity allows them to produce up to 60 million meters of chains annually.

- Specialized Subsidiaries for Diverse Needs

Universal Chain has three subsidiaries: Xinhao Bearing, Universal Transmission Taizhou, and X-POWER. Each focuses on different aspects of chain manufacturing. This structure allows Universal Chain to offer a wide range of high-quality products.

- Industry Expertise and Professional Knowledge

With over five decades of industry knowledge, Universal Chain is a well-known trademark in China. The company’s deep understanding of chain products makes them leaders in the field.

- Commitment to Value and Customer Satisfaction

Universal Chain prioritizes quality and customer satisfaction. Their focus on excellence has made them one of the best high-end chain manufacturers in China.

Conclusion

Stainless steel roller chains stand out as the superior choice due to their exceptional corrosion resistance. This quality protects against rust and degradation. Their heavy-duty capabilities also make them ideal for demanding applications. Industries benefit from the versatility of stainless steel chains.

When sourcing these high-quality chains, Universal Chain is a top supplier. Their extensive global reach, advanced manufacturing capabilities, and commitment to quality make them a trusted partner for over 10,000 clients worldwide.